Salix-Leaf Masks Market to be driven by Major Key Players - 3M, Honeywell, SPRO Medical, KOWA, Makrite, Owens & Minor, UVEX, Kimberly-clark, McKesson, Prestige Ameritech, CM, Winner, Molnlycke Health, Moldex-Metric, Ansell, Unicharm, Cardinal Health, Te Yin, Japan Vilene, Shanghai Dasheng. Salix leaf masks play a significant role in South Korean market and it made lots of people in China think that is Korean style face masks.

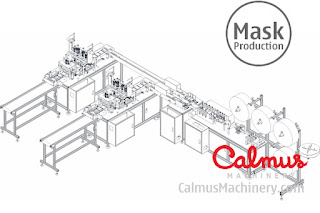

This respirator production line is for producing salix-leaf-shaped KF94/FFP2/N95 face masks and it makes 4-to-5-ply respirators/masks automatically by the following procedures.

1) Unwinding and feeding non-woven fabrics;

2) Feeding and positioning nosepieces (imbedded);

3) Welding and laminating fabrics;

4) Cutting the masks;

5) Folding masks;

6) Feeding and welding earloops.

The above process is done automatically and continuously by PLC.

Features:

1) Fully-automatic.

2) High-speed and speed adjustable.

3) Compact design of 1-to-2: 1 mask blank forming system + 2 earloops welding systems (but on one line)

4) Easy to use. The touch-screen control system makes operation easy.

5) Alarm when the fed material breaks or is in short.

6) A counting system makes the quantity of produced masks visible and make it possible to set the mask quantity of each stack for the conveyors.

Specifications:

Power supply: 12 kW

Capacity: max. 70-80 pcs/min

Weight: 3,000 kg

Dimensions: 7,100(L)*4,600(W)* 2,200 (H)mm

Site level: class 100,000 cleanroom

Compressed air: 6 bar, pre-filtered, 23L/min

Fold symmetry: ±2mm

|

Fully-automatic Salix-Leaf KF94/FFP2/N95

Respirator Mask Production Line - 1 |

|

Fully-automatic Salix-Leaf KF94/FFP2/N95

Respirator Mask Production Line - 2

|

|

Fully-automatic Salix-Leaf KF94/FFP2/N95

Respirator Mask Production Line - 3

|

|

Fully-automatic Salix-Leaf KF94/FFP2/N95

Respirator Mask Production Line - 4 |

|

Salix-Leaf KF94/FFP2/N95

Respirator Mask |